Surface preparation

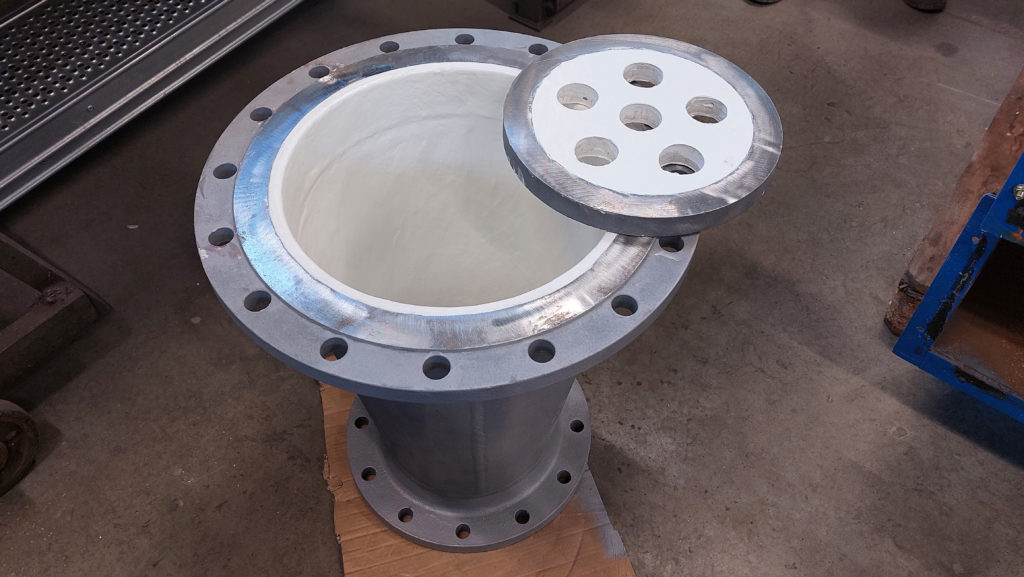

Fabrication of the piping piece and orifice with respect to the location of the coating. Decontamination of grease and soluble impurities. Surface preparation by abrasive blasting according to ISO 8501-1 to purity grade Sa 2½.

Application of masses

Applied Products:

PLASMET ZF, CORROCOAT EB

Applied coating systems:

NDFT 2 000 μm (internal coating)

NDFT 120 μm (outer coating)

Applied substrate:

Inner/outer part of pipe part and screen; carbon steel

Procedures:

- Production of the pipe part and the screen with regard to the location of the coating

- Degreasing and decontamination of soluble contaminants from the surface

- Surface preparation according to ISO 8501-1 to purity grade Sa 2½

- Application of PLASMET ZF primer

- Application of CORROCOAT EB building material

- Application of PLASMET ZF external parts

- Carrying out the relevant quality tests according to the PKZ

CORROTECH ENGINEERING s.r.o. provides highly professional services in the field of surface preparation and application of special coating systems for the most demanding stress environments and various industrial equipment. CORROCOAT series coatings filled with special glass microflakes enable a significant extension of component life even in difficult cavitation environments.

CORROCOAT has been successfully fighting corrosion for more than 45 years. It uses innovative mechanical engineering combined with anti-corrosion technology to provide long-term protection for both new and damaged equipment. It uses special composite and structural coatings in conjunction with technical processes to individually address corrosion problems. With a focus on quality, refurbishment procedures are a proven, cost-effective weapon to win the battle against corrosion in the long term.