Application of coatings

Our company offers anticorrosion service based on the use of technology through the application of industrial coatings. We carry out workshop applications in our own plants or on-site applications. We use application methods and technologies with state-of-the-art equipment. Our team has unrivalled expertise in the application of industrial coatings for process equipment, concrete surfaces and steel structures. We have an extensive and specific range of coating systems and application procedures. We perform surface preparation and application of coatings as well as high-rise work with rope access.

Application of special materials and composites

We are the only company in the region to offer the advanced CORROCOAT and REZORECT corrosion protection service based on a range of cutting-edge glass microflake composite technologies. We carry out special workshop applications in our own plants or on-site applications. We use unique application methods and technologies with state-of-the-art equipment. Our team has unparalleled expertise in the application of specialty coatings for the heaviest service loads. We have an extensive and specific range of unique coating systems and application processes.

Lamination and mould making

We have extensive experience in the implementation of lamination reinforcement in coating systems, which significantly extends the service life of critical parts of applied structures under extreme service loads. The application of laminating technology as part of a coating system requires maximum expertise and experience to ensure its long-term reliable functionality. We have an extensive and specific range of unique coating systems based on special glass microfiber composites combined with curing and lamination techniques for extra protection of critical infrastructure. Our portfolio of work with lamination also includes modelling and mould making.

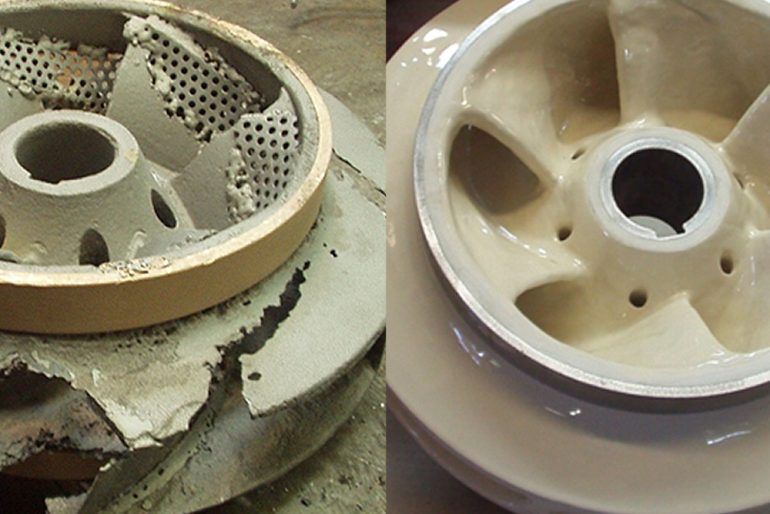

Renovation of damaged surfaces

Engineering in conjunction with corrosion protection. We provide professional repairs, overhauls and servicing of pumps, valves and auxiliary components of all shapes and sizes. We have complete reverse engineering in our own, specialized plants, a wide range of materials leading to increased performance of the equipment itself (shaft renewal, dynamic balancing, etc.). We offer high quality and expert service associated with maintenance and refurbishment of utilities using composite materials, resulting in a reduction of costly downtime and more than 50% of acquisition costs. The combination of high-performance composite materials and experience in engineering give us a unique opportunity to have the upper hand in the fight against corrosion.

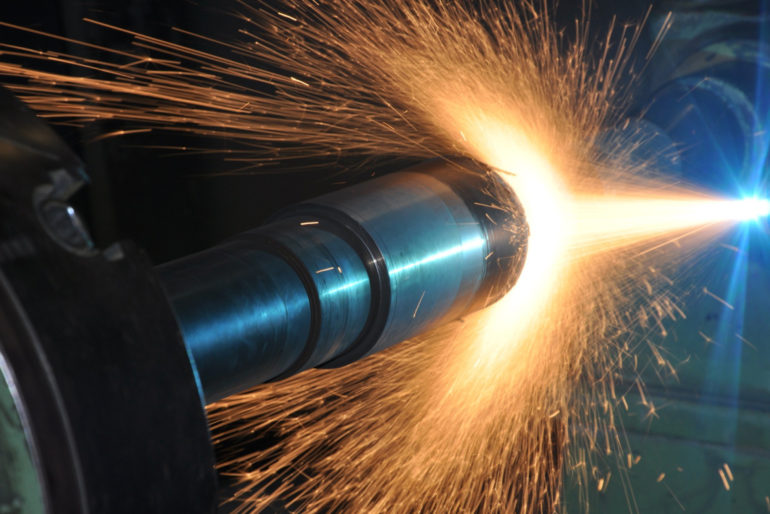

Application of hot spraying

Ensuring the quality and durability of the coating starts with careful selection of the most appropriate method and type of coating material given the severity and aggressiveness of the operating conditions. We offer the possibility of using the technology of advanced modular system of spraying with oxygen and acetylene for hot spraying of a wide range of alloys and other materials in the protection or renovation of various mechanical components. A range of alloys provide excellent wear resistance from metal on metal friction, corrosion, abrasion and erosion. Our CastoDyn DS 8000 enables hot spraying to be applied to complex internal holes or parts with complex geometries.